Bioindustrial Manufacturing

BioMADE unleashes the power of biology to help create and domestically source the manufactured goods that people use every day. Up to 60% of materials in the global consumer product supply chain can be produced using biology and by 2030, most people on the planet will have consumed, worn, or been treated by a product of emerging biotechnology.

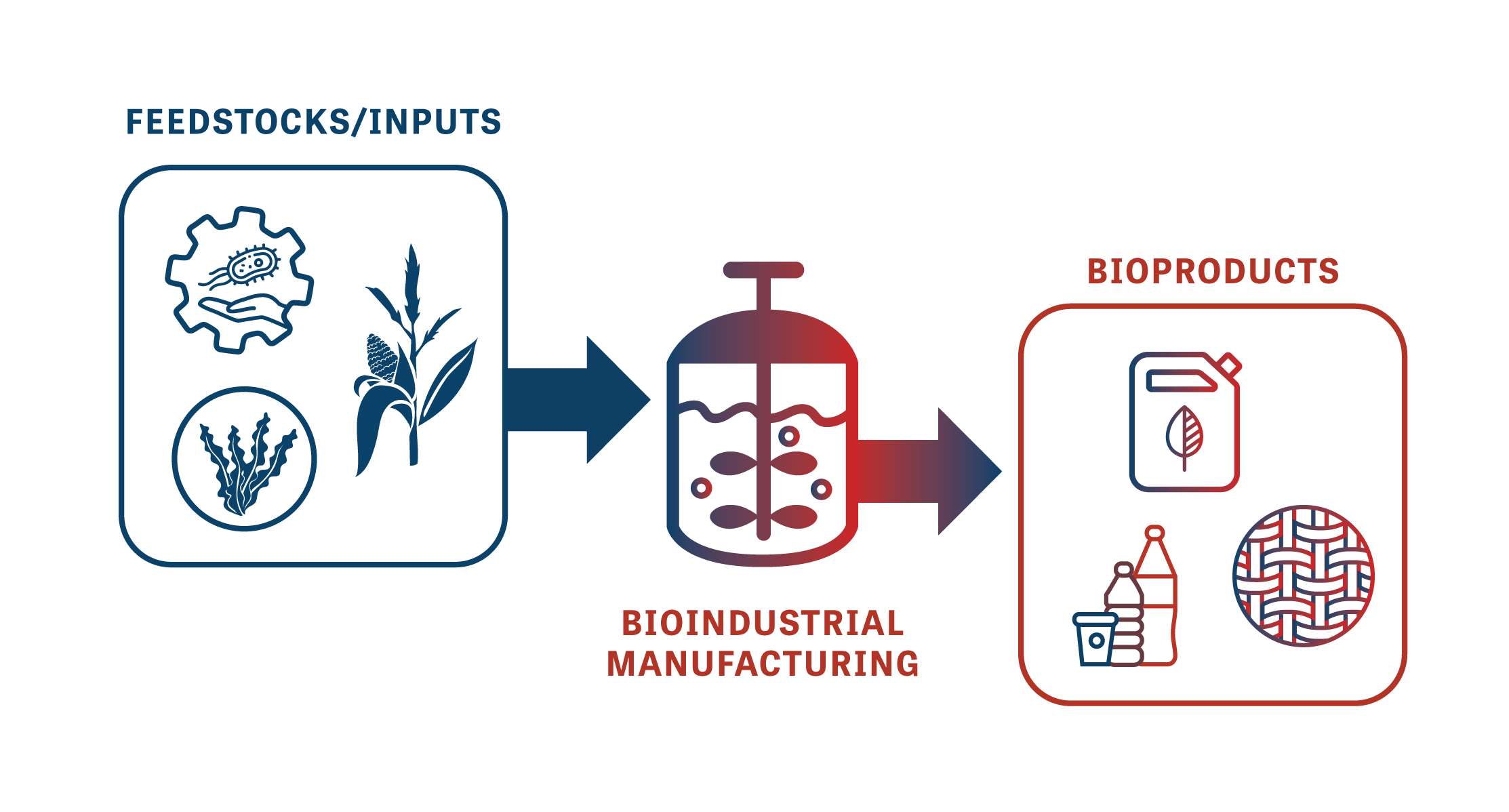

Bioindustrial manufacturing uses biological systems to convert agricultural feedstocks and waste streams to high-value chemicals, materials, textiles, fuels, bioplastics, and other products. Because bioindustrial manufacturing typically uses feedstocks such as corn, soy, and sugar beets, American farmers will benefit from the new markets created by BioMADE technologies, and rural communities will benefit from the manufacturing jobs creating the associated products.

Biotechnology and bioindustrial manufacturing are not new concepts – fermentation was first harnessed by humans over 10,000 years ago and is used to produce products like cheese, yogurt, and beer. Today, innovative U.S. companies are taking this to the next level and unlocking a new future where everyday chemicals, materials, plastics, textiles, and more are safely manufactured in the U.S. using biology.

The U.S. bioeconomy is currently worth at least $950 billion – and growing every day. That’s more than 5% of U.S. GDP. BioMADE supports its members to create marketable products through bioindustrial manufacturing, further catalyzing this domestic economic growth. Bioindustrial manufacturing has the potential to impact all sectors of the economy and all areas of society, helping the U.S. become more self-sufficient and sophisticated in manufacturing.

Consumer Applications

Plant-based nylon and other durable textiles and fibers for clothing and shoes

Biodegradable plastics and compostable packaging materials

Bio-butanediol used to make spandex, compostable tote bags, coffee capsules, food packaging, and more

Probiotics, fragrances, beauty and personal care items

Healthier cooking oils and sweeteners, and more nutrient-dense infant formula

Critical minerals that go into cell phones and semiconductors

Everyday products like fertilizers, detergents, paints and coatings, and adhesives

Photos below © Algenesis, Cambium, Amyris, Eco-Shot, Debut Biotech, Biomason, Geno, Novonesis

Defense Applications

Novel and performance-driven chemicals, materials, and textiles

Natural rubber made from dandelions

High-performance aviation fuels

Bio-based laser eyewear protection

Anti-corrosives, lubricants, adhesives, and sealants

Thermal coatings, high temperature-resistant foams, and thermal protection systems

Energetics and energetic precursors

Deployable production of fuels, lubricants, and other critical materials

Rapid, point-of-need infrastructure production with biocement

Lightweight composite materials, shotgun wads, and ammunition links

Other needed supplies that could be produced on-site at point-of-need – reducing vulnerable convoys – and that degrade quickly so as to not compromise warfighter position

Benefits of Bioindustrial Manufacturing

Enhances national security by creating more robust and resilient domestic supply chains

Protects and enhances warfighters

Creates needed products and materials without foreign inputs

Re-shores manufacturing jobs and establishes the U.S. as a self-sufficient and global manufacturing leader

Builds a globally competitive STEM workforce

Supports American farmers and enhances rural development