Technology and Innovation

BioMADE’s Technology and Innovation program is bridging the gap between benchtop research and at-scale manufacturing to propel new biotechnology products from the lab to the commercial market. Bioindustrial manufacturing has the power to fundamentally change how we produce goods in America, creating products that positively impact our everyday lives.

Through BioMADE projects, members have scaled up new products, brought new products to market, reduced costs and improved product outcomes, invented new processes and equipment, and more.

BioMADE focuses on helping the industry cross the Valley of Death – the challenging time between prototyping and commercial-scale success – by focusing research on MRLs 4-7. Learn more about adapting MRLs for bioindustrial manufacturing here. BioMADE’s programmatic work moves biomanufactured products and technologies through to commercialization, illustrated below.

Photo above © Schmidt Sciences | Capra Biosciences

Manipulate

To ease the transition from lab to production-scale manufacturing, this area of work focuses on developing predictive models, data analytics, strain engineering, computational tools, and more. Learn how members are benchmarking synthetic biology product development, simulating scaled-up fermentation bioprocess conditions, and improving intracellular product recovery from yeast systems through BioMADE projects.

Photo at right © Ginkgo Bioworks

Accumulate

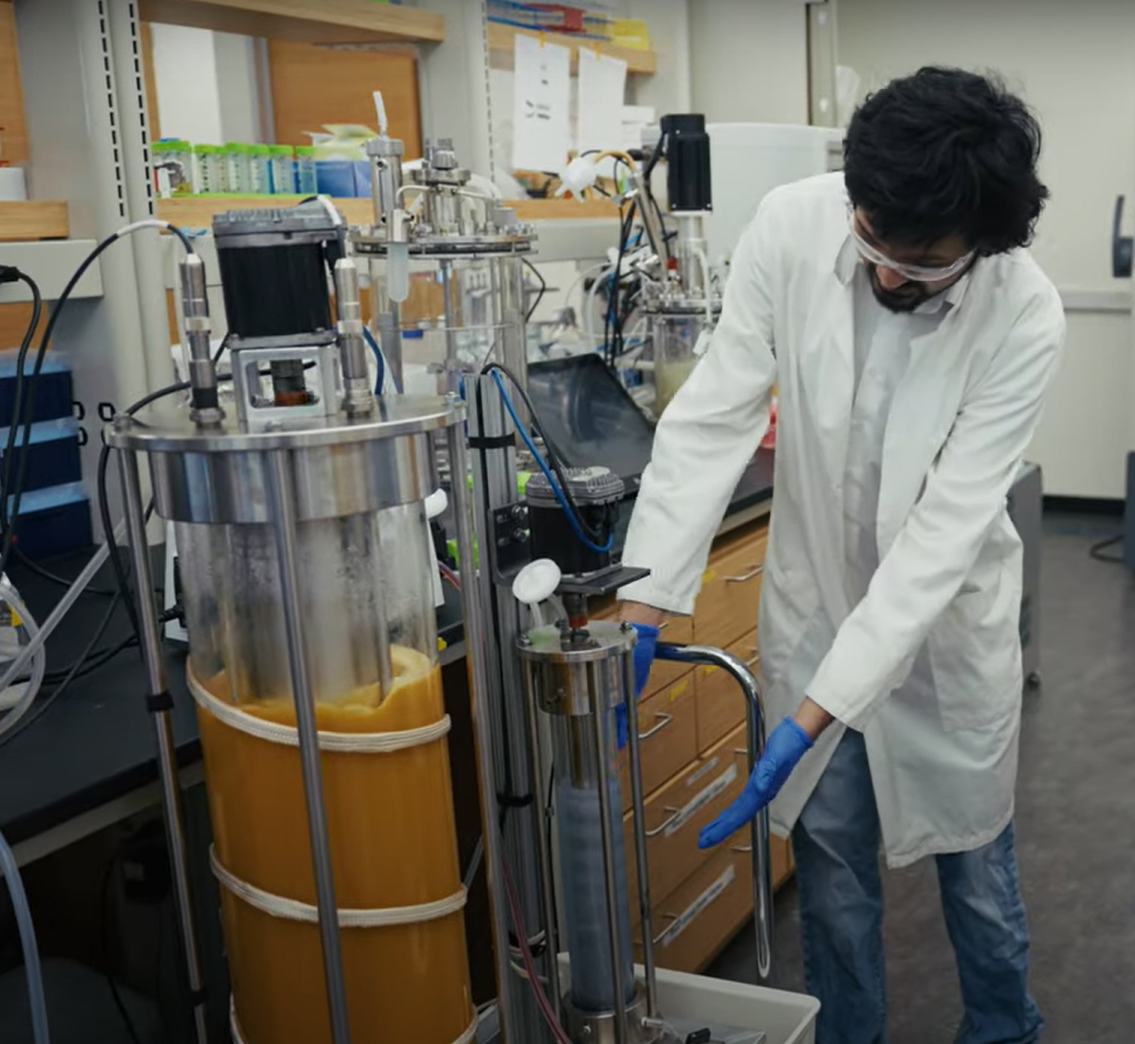

As the bioindustrial manufacturing industry scales up, industry needs to be able to produce relevant quantities of materials as quickly and efficiently as possible. This research area focuses on cost reduction strategies, sensors and assays, equipment design, material testing and evaluation, and more. Through BioMADE projects in this research area, members have scaled up the production biopolymer precursors; are developing new fermentation equipment and sensors; upcycling waste; and enabling decentralized manufacturing of needed materials.

Photo at right © North Carolina State University

De-Risk

Exploring new technologies can be risky for industry – particularly when it comes to scale-up and downstream processing. This research area helps alleviate that risk through data collection, recovery roadmapping, and downstream processing infrastructure. BioMADE projects have made substantial progress in in situ toxic product removal and are making better predictions for scale-up performance. Members have also moved toward commercialization of products like performance textiles, aviation fuel, and novel bioplastics.

Photo at right © Amyris

Execute

Moving from lab-scale production to at-scale manufacturing can present challenges related to infrastructure, market demand, and technology protection. This research area supports the transition to production partners through projects focused on protecting domestic biomanufacturing IP and trade secrets and capturing and organizing data required to advance a technology to commercialization such as legal, regulatory, supply chain, workforce, physical and cybersecurity. Learn how members are scaling up production of carbon black and natural rubber – which are important for tires and numerous other applications – for commercial readiness.

Photo at right © BioMADE

Commercial Readiness

Ensuring commercial readiness and market demand for new biomanufactured products is critical to the success of the industry. This research area focuses on integrating simulation systems, technoeconomic analysis, and life cycle assessment of developing biotechnologies. Through BioMADE projects, members scaled up and commercialized production of a recombinant probiotic for poultry health, and of fatty acids precursors for aviation fuel; improved supply chain predictability with a modeling tool; and developed a state-of-the-art methodology for fermenter design.

Photo at right © Checkerspot

Digital Backbone

BioMADE is creating a Digital Backbone which will securely collect, manage, analyze, visualize, and share data from strain engineering through commercial scale-up across the bioindustrial manufacturing community. By streamlining technology transfer, collaboration, and broad dissemination of data and analytical capabilities, the Digital Backbone will ultimately bolster U.S. manufacturing capabilities and protect against supply chain disruptions.

BioMADE projects are:

Reducing waste streams and improving product yield: BioMADE projects have discovered ways to reduce waste streams by 100-600% while also improving product yields by almost 20% through innovative uses of waste gas, agricultural, and municipal feedstock sources

Making production more efficient: Members are producing molecules more efficiently, thanks to developments in continuous fermentations systems and in situ separation and removal

Saving costs: Biomanufacturing research has been made more affordable through models that let members compare stirred tank versus bubble column designs and configuration prior to investing in large-scale equipment, sensors that utilize Raman spectroscopy, miniaturized free floating sensors, and AI/ML models for inline monitoring and control during fermentation

Producing needed materials: BioMADE members are producing performance textiles, Vitamin A, high-temperature resistant composite materials, natural rubber, aviation fuel, plastics, and more products for consumer and defense applications

Learn more about BioMADE’s Technology and Innovation projects here.

Members can access best practices, datasheets, publications, and more resources that were developed through BioMADE projects. Find all resources here.

To learn more, members can also read BioMADE’s Technical Roadmap – Strategies and Priorities for Advancing Bioindustrial Manufacturing Processes and Technology to Commercial Readiness – available in the Member Portal.

Photo left © Schmidt Sciences | Iowa State University